Second time right. Perfect static test.

Goals:

- Evaluate use of 8 bates grains stacked on top of each other in a 54mm motor.

- Use a 5gr igniter charge consisting of 2,5gr commercial BP and 2,5gr magnesium to boost the start up pressure for instant ignition.

- Use checklist for motor assembly

- Use isopropanol for grain priming

- Test Viton o-rings “46x4mm Precisie O-ring FPM (Viton®) 75° compound 51414”

- Measure temperature of casing near the nozzle

Excel file – 54mm, 8 BATES grains, KNDX 6535 Static Test II – 27.03.10.xls

Video – DECA_14_-_Static_Test_II_-_27.03.2010

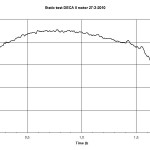

Thrust curve

- Peak thrust – 910N

- Average thrust – 680N

- Burn time – 1,8s

- Total thrust – 1366Ns

- Propellant weight – 1155,5,gr

- ISP, delivered – 120,5s

Pc . At = ( F / g ) / CF

Pc • 2,02= ( 910 / 9,81 ) / 1,10

Pc = 36,5 Bar

CFmax = 1,26

Throat aera ( At = 2,02 )

(g = 9,81 m / s)

Notes:

- Grain making proces is as described here is excellent and resulted in 8 beautiful bates grains. Average density of 99%, AGAIN! However, release of the tapered core took some more persuasion then previous releases with the newly machined core.

- Weight of the motor – loaded but excluding igniter – was 2633gr of which 1155,5gr of KNDX.

- Pyrogen coating: 4 top grains all surfaces, lower 4 grains only the ends coated with commercial 3F BP. BP needs to be grinded in a mortar before being mixed with isopropanol. Isopropanol evaporates much less rapid then the aceton based NC lacquer thus giving you more time to work. Total coating on all grains = 2,3gr BP.

- Igniter: 5,0gr (2,5gr commercial 3F BP + 2,5gr of magnesium).

- Weather was fair, temperature during testing 9-11° C.

- Again, the bolt holes in the casing do cause significant damage to the o-rings and slice off small sliffers or leave cutting marks when inserting the nozzle or forward closure. No leakage at all.

Conclusion:

- 8 bates grains seems to works just fine although the burn time was longer than expected. No erosive buring was evident. Burn time was the same as test #1. This could be either a result of the 9° C temperature or the high density.

- Igniter worked better than expected. Magnesium solved the instant ignition problem for this motor. Please be carefull: This is a potentially dangerous mix. In the presence of moisture, the Mg will react, generating heat, to the point where ignition of the BP may occur. I wouldn’t recommend mixing this up in advance.

- Checklist worked like a charm, easy breezy motor assembly. Small notes to be revised and version as per 19.04.2010 can be found here.

- 100% isopropanol (IPA), as obtained from a local printing office, works OK for priming the grains and given the results of the test it will be used for all future priming jobs.

- Viton o-rings from Eriks were of excellent quality and performed better than the NBR o-ring which melted after the burn. However, the bolt holes consistently made 12 evenly spaced cuts in the o-ring (12 cuts from 2 rows of 6 bolt holes). O-rings are therefore considered as single use. Could be re-used for the recovery electronics bay.

- Temperature peaked 170° C at 30s after burn out. Quick search on the internet reveals that the aluminium temperature should be kept at under 250° C to prevent degradation of the aluminium.

Library:

DECA 14 – 2010 Rocket Motor – Assembly & Propellant Loading Manual – 17-05-2010 – All you need to know.

DECA14 11 DEGR 600NPV 27-3-2010 – Raw data from test: 600N/VDC

54mm mold spring loaded – Compression mold drawings