SLD2024-02 - On Friday 31-05-2024, we had the 10th anniversary of the Intimidator 5 rocket and its 9th flight. It is not often that we have a 10 year old rocket still in flyable condition. Surely she has her battle scars, the paint job isn't as shiny as it once was but she still flies straight and todays launch was no different.

SLD2024-02 - On Friday 31-05-2024, we had the 10th anniversary of the Intimidator 5 rocket and its 9th flight. It is not often that we have a 10 year old rocket still in flyable condition. Surely she has her battle scars, the paint job isn't as shiny as it once was but she still flies straight and todays launch was no different.

The SARON launch day was attended by the rocket organizations DARE, NAVRO and NERO. Two student teams AQUILO (InHolland Delft) and RISE (University of Twente and the Vrije Universiteit Amsterdam) flew their rockets from the NERO launch rail which included the NERO pre-flight rocket inspection and sanity check. With DARE and its 50-100+ students on the left, central launch control table in the middle and AQUILO, RISE and NAVRO on the right the flight line was cleanly organized. Weather was cloudy with light showers in the morning, ligth wind from the N-NE direction. Launch rail was set at 55° azimuth and with an 83° elevation.

Intimidator 5

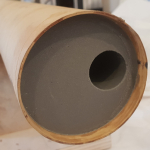

After a 3 year break, where I got distracted from rocketry (but never completely left the hobby), it was time to repair the damaged Intimidator 5. During the last flight in 2021 the motor eyebolt twisted loose and the fincan separated from the rest of the rocket under main parachute. As a result the fincan tumbled in a free fall from 300m and 'landed' in the heather breaking a fin. The fin was epoxied back into place with "Wildman style" injected fillets and additionally all 3 fincan cavities were filled with 2-component PU foam for extra rigidity.

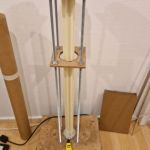

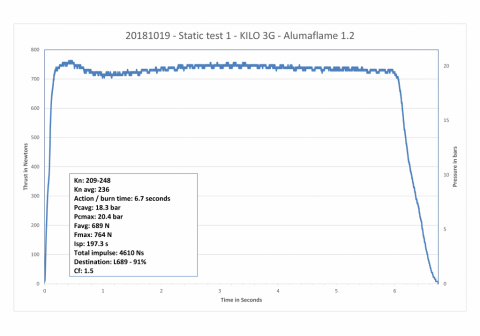

For motor selection it was decided to develop an experimental APCP motor. This motor was designed for SARON launches at the ASK 't Harde in the Netherlands. Some of the design criteria were:

- Apogee between 2-3km.

- Relatively easy reload fabrication

- High thrust for good launch rail exit velocity.

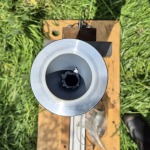

- Re-use existing motor hardware, especially the 22mm throat, full graphite nozzle.

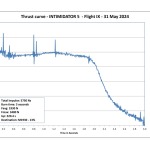

For more info about this motor please click this link - KILO half PML liner P80F.

The flight

With the rocket parts only needing shock cord connection and shear pin installation assemble took no longer than 5-10min. Powering on the video camera and RDAS was uneventful and we headed back to the flight line. After a 10s count down the APCP rocket motor quickly pressurized after which the rockets left the rail pulling 15 G's only to disappear in the clouds soon after. The rocket was tracked by the latest iteration of the LoRa GPS transponder made by LD, connected to the RocketLocater-app. Although we could not visually track the rocket anymore, the position and altitude were sent back live to the app. We quickly concluded that, at an apogee of 2.600m, the rocket had separated correctly while also accidentally deploying the 72" IRIS - FruityChute main parachute. A long decent awaited with the rocket just landing in the first tree line. A light tug made the rocket fell from the tree and was recovered undamaged. Upon examination of the data, the extension / tensioning of the shock cord at apogee sent a -31G shock through the rocket thereby shearing the M3 nylon shear pins holding the nose cone in place and deploying the main parachute. Probably caused by: 1) BP-charge-creep (every next flight a little extra BP for safety) and 2) due to the shorter APCP motor there was more space for the shock cord to be very loosely packed with less resistance to absorb some of the peak loads. Furthermore we could visually see the main deployment BP charge fire at 300m meaning the RDAS functioned correctly. For next flight we will reduce the shock cord peak loads by adding some elastic covered kevlar in parallel of a section of shock cord.

20240608 - Post-flight testing of the BP apogee separation charged showed that even at 1gr of 4FG BP the rocket separated. For next flight a 2gr, 4FG BP separation charge is recommended.

AQUILO

The students from Inholland launched their Aquilo VIII rocket on a 2G KILO-style motor with a perfect recovery in clear viewing range of the flight line. Furthermore they static tested a 4G KILO-style motor with a KNSB reload with a funky thrust curve.

RISE

Being the new-kid previously launching at HPR launches. I liked the approach where the focus of the team was to get the rocket flying, using a COTS, 3G 54mm Cesaroni motor, keeping it under 1km and getting the basics dialed in.

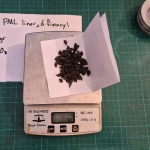

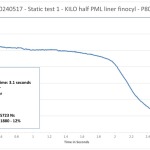

On May 17th 2024 the KILO half PML liner APCP motor was tested.

On May 17th 2024 the KILO half PML liner APCP motor was tested.