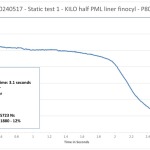

On May 17th 2024 the KILO half PML liner APCP motor was tested.

On May 17th 2024 the KILO half PML liner APCP motor was tested.

This motor was developed to be launched in the Intimidator 5 rocket for launches in the Netherlands.

Design criteria:

- Apogee between 2-3km.

- Having limited total impulse 5.000-6.000Ns not overshooting the wavier or needing to cancel a flight in less favorable wind conditions.

- Relatively easy reload fabrication

- It takes quite of bit of time, several uninterrupted hours, for a good mixing/casting session. Hence it would be efficient when 2 grains could be made in a single session.

- High thrust for good launch rail exit velocity.

- For good rail exit velocity of the rather heavy Intimidator 5 rocket.

- Aggressive core geometry to be used from preferably an existing, stock foam core.

- Predictable, fast burning, pourable APCP propellant to be sourced.

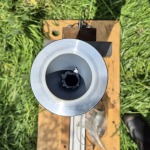

- Re-use existing motor hardware, especially the 22mm throat, full graphite nozzle, foam core.

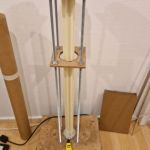

- Half PML liner motor hardware / casing was already available from a previous KILO 3G pourable Alumaflame motor design.

- Using the 22mm throat, full graphite nozzle. Required a fast burning propellant at low-ish 200-300 Kn.

P80F propellant

In our search for a fast burning, pourable APCP propellant, AV kindly offered the ‘Fast’ version of his thoroughly proven P80 formula. P80 is a pourable, 80% solids formula. Consisting of 70% AP and 10% Al. This basic formula is well known among the amateur experimental rocket community. It’s considered a very simple but high performing formula; however the difficulty is to make it pourable due to the high solids content. In a previous attempt making this basic 80% solids formula with 200um AP resulted in a difficult extrudable, almost packable propellant. Here comes AV’s P80F formula into play. By carefully selecting particle sizes and additives the propellant almost became as viscous as Slow White or the 66-12 formula. Some key take-ways of this formula: 200um spherical AP, ball milled AP and bi-modal spherical aluminium. Together with HTPB, DOA (in 2:1 ratio), 0,5% ferrocene burn rate catalyst, Triton X-100 surfactant, silicone oil and MDI for curative. Although the main ratio of 70%AP and 10% Al remains the same, this formula resulted in a rather stiff but pourable propellant.

Preparation and casting information can be found in the below description of the photos. Some notes & tips:

- 72hr after casting dissolved the foam core.

- 50/50 aceton/xyleen mix of 300ml was prepared. 200ml in first pour to dissolve the foam core and 100ml second pour to clean the residu.Keep casting base in place before dissolving core to avoid spilling the aceton/xyleen mix.

- 3% waste just barely enough, next mix 4% wast for a 5.6kg batch and 6 finocyl. Use the 10l bowl nex time fr a 6kg mix.

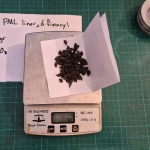

- Ball milled 400gr AP for 3 hrs = 2 ball milled AP batches to get 800gr ball milled AP.

- Dissolved ferrocene (sieved 300um) in half of HTPB/DOA liquid (plus 10gr extra to take into account residue) the day night before in sauce pan at induction plate set to 60 degrees.

- HTPB/DOA liquid temperature was approx.. 65-70degrees. Ferrocene smells!!!

- The finer the particles the easier to dissolve, takes about 30-60min. Also after cooling down to room temp the ferrocene remained dissolved.