GIGA IV – Common bulkhead

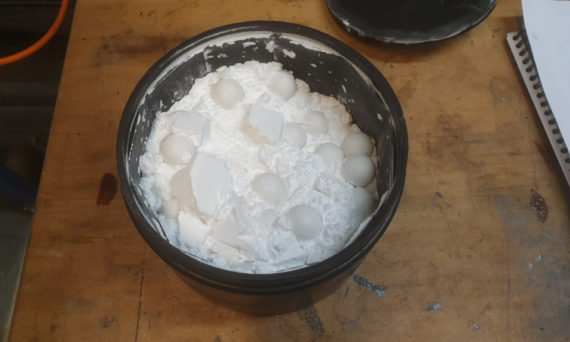

One of the design changes for the GIGA IV is a common bulkhead to join the previously central avionics bay of GIGA I-III (in control of recovery) with the updated nose cone electronics (camera and GPS tracker). With this modification there is no longer space for a separate main parachute compartment as can be expected